Innovative Design

- Solutions to problems so you maximise revenue We design products to be as damage resistant as possible. This is built in at the outset, so you can be confident in its durability. Good design maximises rental potential. Check out our modular braces to see what we mean.

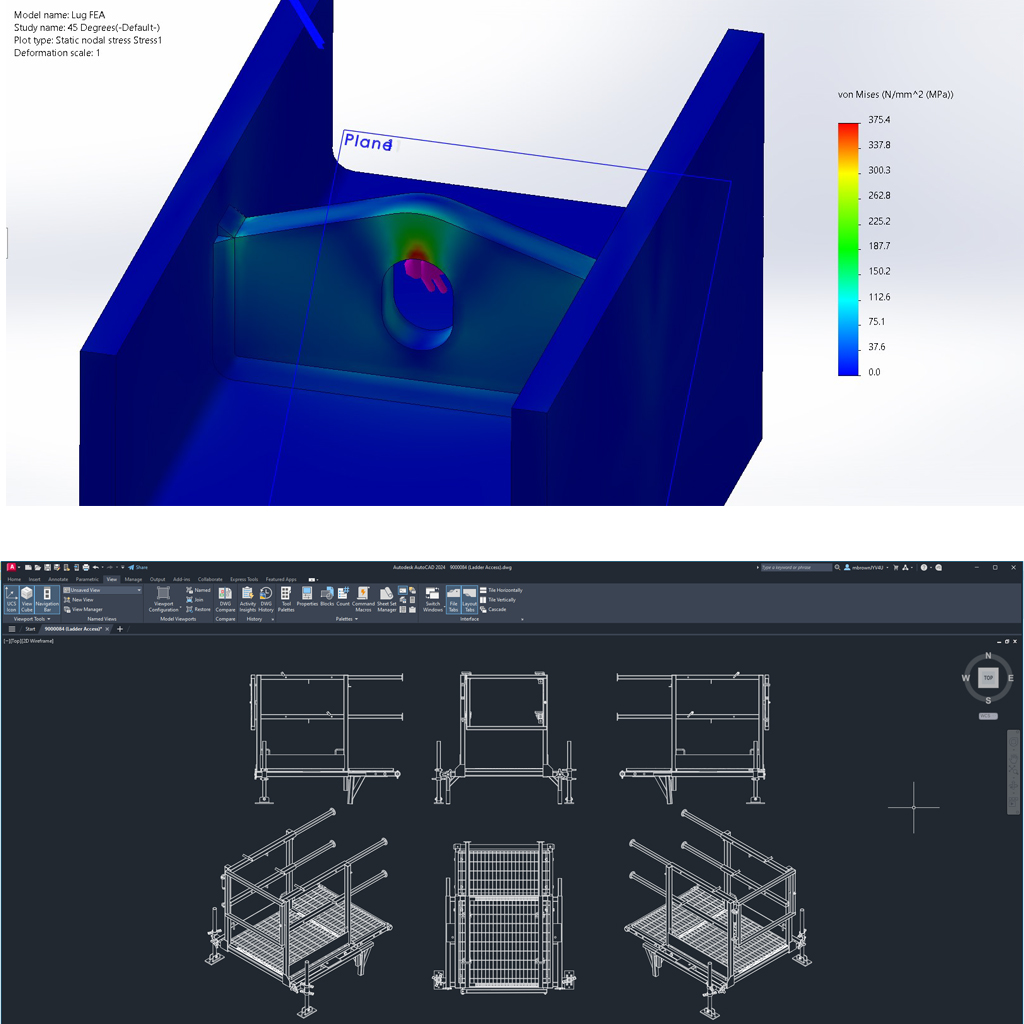

- State of the art software Our sophisticated software allows us to bring products to life before we have even built them. We can see what happens when we alter materials, sizes, thicknesses, weight and more. 3D models show us how our designs perform before we begin making them, so we can get it right first time.

- Independent assessment and verification Our designs are assessed and verified by independent chartered professionals to verify we have got it right. Independent Chartered engineers run through our calculations. Finite Element Analysis (FEA) software shows us tolerances to loads and stress. Our testing regime is comprehensive, so you can have confidence in our products.

- Right first time ethos We build cost-effective products using innovative design to get it right first time before we begin manufacturing. Virtual testing regimes identify whether we need to refine the design and where to ensure they cope with the loads they find themselves under in the field.

Further detail

Our mission to design and manufacture durable trench shoring products for hire companies begins at the design stage. Our skilled design team are also highly trained engineers that understand the practicalities of the trench shoring hire market. This helps us to get design right first time whether we are developing a new range of products or incorporating specific features for an individual hire company.

British trench shoring techniques often see equipment installed and removed multiple times during a project. This increases the potential for damage and the need for repair. Right first time design builds products that:

- perform well under load

- are resistant to over-exuberant installation practices

- have tolerances built in beyond recommended load capacities

Our attention to design doesn’t stop at product durability and meeting standards. We have an eye on your customers, so they can hire trench shoring equipment from you that is easy to assemble. We understand the features they need to make assembly, installation and removal easy and rapid while creating a safe working environment they can rely upon. Importantly, we understand that minimising parts or making them interchangeable means everything arrives on time, assembles easily and reduces costly training. It also helps reduce your fleet costs, legacy costs and stock holding costs.

You can count on Jayville products to be the most robust on the market thanks to their design. If you are looking for shoring products to complement your current range or a specific design to ensure your products provide the solution to a client’s shoring problem then talk to our innovative design team.